Employee protection policies help improve a company’s performance.

When the first workplace safety systems and tools are implemented, new necessities related to these changes emerge. That’s why it’s when it comes to occupational health and safety it’s so important to be in a constant state of evolution – to keep up to date with the changes in the field and to improve the conditions of our employees.

At Claitec, we believe in continuous innovation. And that’s why we constantly update our knowledge of technology – to implement improvements in our range of products and services. After observing a number of opportunities to better the driver’s inhibitor, we decided that it was necessary to implement some changes. Today, we are thrilled to report that after these modifications, we have received very positive reviews and customer ratings in the United States and England, among other countries.

What’s the purpose of the Inhibitor?

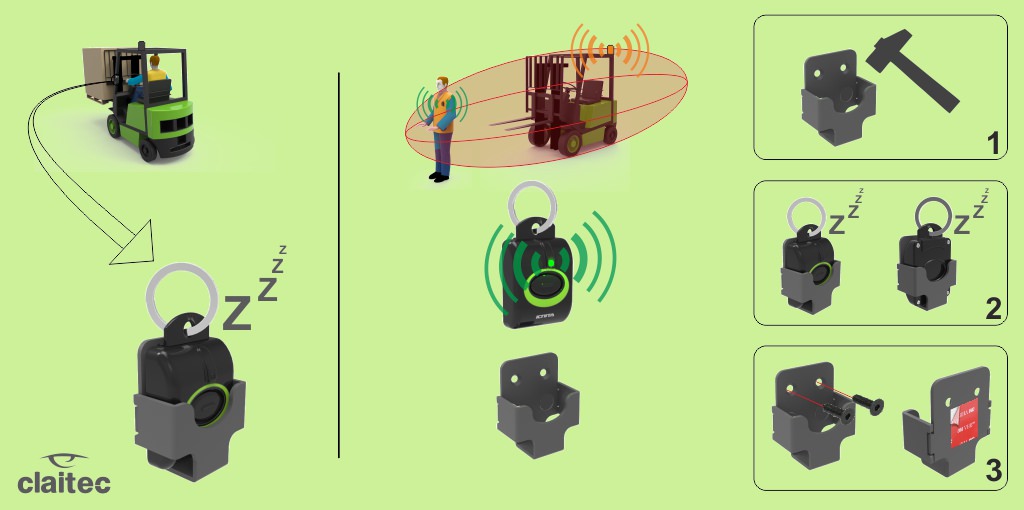

Most businesses tend to have more than one truck. At sites where companies care about the protection of their workers, these carry a protective tag known as T-10 which, is part of an efficient Pedestrian Alert System. But what about the truck’s driver? Doesn’t this protection tag conflict with the detection system?

Here is precisely where the Inhibitor comes in.

The inhibitor is simply a space where forklift drivers are able to leave their protection tags so that these are not detected by other systems. This allows them to drive the truck safely, while the Pedestrian Alert System is activated. In addition, they can leave it aside and perform picking operations or control of goods with the assurance that the Pedestrian Alert System will protect them at all times.

Similarly, the driver’s inhibitor also ensures the proper functioning of the Anti-collision System, as drivers are able to operate the truck without the interruption of the PAS solution, allowing the anti-collision system to run properly.

Improvements in the Inhibitor

When Claitec produced the first versions of the Inhibitor, our customers welcomed the added value it brought to their operation. However, given their constant exposure to shocks and falls and their potential for breakage, we found out there was room to improve its resistance levels.

In addition, we learnt from other customers there were other areas the Inhibitor could also improve on. For example, the product was somewhat limited in the sense that only if placed in certain location, was it able to work properly. Some operators placed it upside down and caused the inhibitor to be unable to fulfill its functions.

Thanks to the feedback and support from our customers, we redesigned the product, and we are thrilled with our customers’ positive feedback. Firstly, we’ve changed its design so that it works when the protection tag is placed in any position. We’ve maintained the double-sided adhesive in order to facilitate the attachment of the product.

The new version is made of steel, which virtually eliminates the problem of resistance that our customers had observed with the previous model. In addition, it is now possible to attach the inhibitor with screws, which greatly increases its durability and shock resistance.

We have already tested the new inhibitor. A very, very, very good design.