How do I get the Tag T-10’s battery to last longer? What do I need to do to stop changing batteries so frequently?

Our customers ask us questions like these concerning the battery life of the T-10 constantly.

That’s why, in this post we’ve decided to analyze these systems and their battery usage, as well as discuss the measures that can be taken to maximise battery life and minimise the number of battery changes required.

It is important to note that the battery consumption depends on many factors and as such, it’s very difficult to be precise about the exact life expectancy of the battery.

How does the TAG T-10 system work?

To better understand the factors that affect the life of the battery, let’s start by analysing how the entire system works.

Most of the time the Tag is in “sleep” mode – in this case, power consumption is minimal (microamperes).

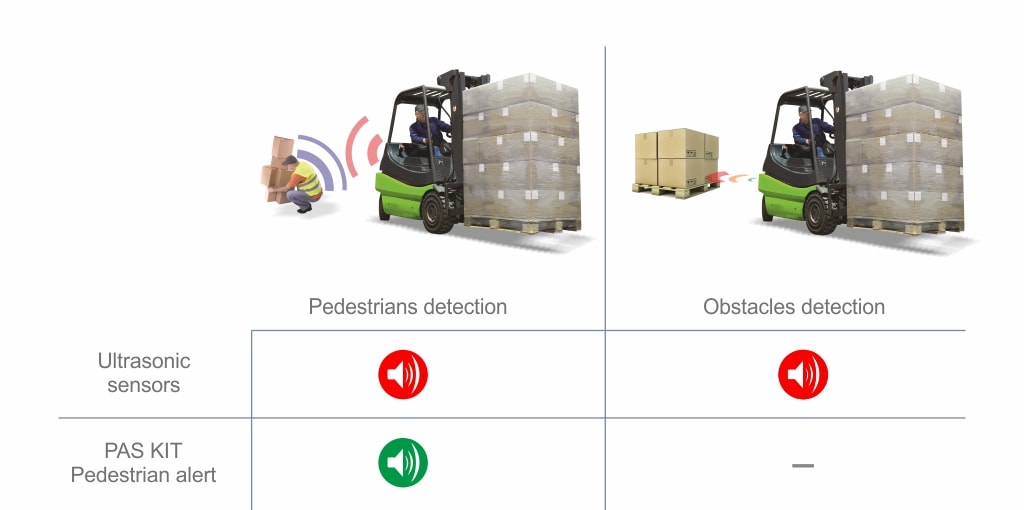

When the Tag is located within the forklift or the verification antenna’s detection area, it switches to “active” mode and it communicates its position to the forklift’s AC-50 device. In this state the Tag consumes a lot more current (milliamps) but only during short periods of time.

Thus, the longer the Tag is in “sleep” mode, the longer it will last.

What sort of duration can we expect?

The answer to this question depends on your usage.

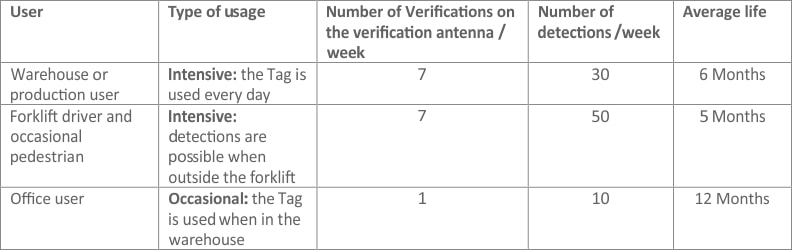

The following are three examples we’ve observed commonly:

Factors that influence the battery’s life expectancy

One of the most important factors is the original quality of the battery.

There are many different brands and – being a standard CR2450 button battery -, it is very easy to find it in any hardware store. However, not all batteries are manufactured following the same quality standards so it is highly recommended to use a renowned brand such as Maxell or Varta.

Environmental factors are also very important.

Batteries are chemical elements and the reaction of these elements is sensitive to temperature and humidity. The environmental conditions in the location where the battery is stored or where the Tag is used will have either a positive or a negative impact on the life of the battery.

Other factors relate to the battery’s usage. For example, we found cases where the Tag is stored near a verification antenna or in a busy forklift zone so that the Tag is active a lot more than it is really necessary.

If the forklift driver does not have the habit of turning off the machine before getting off, the detector will activate the Tag for a few seconds, something which – if repeated several times a day – can also have an adverse effect on the battery’s life.

Tips to help you extend the life of the battery

The following are some easy tips that will help you extend the life of your Tag T-10’s battery:

- Your best option is to rely on The Inhibitor, a device that optimizes the Tag’s use to its maximum (when the Tag is inside the Inhibitor). It is especially suited to make the most of situations where the Tag should not be in active mode and to ensure that consumption is at the lowest possible level.

- Reduce the number of times your staff verifies their Tag. It is recommended to find a balance between ensuring that the Tag is running and spending the least amount of battery possible.

- Ensure that driver turn off their forklifts when not in use.

In short, there’s really not a magic solution to help you postpone the changing of the Tag’s batteries. However, there is a very effective solution – to save a little bit of energy every day. Small changes will indeed result in a significant extension in battery life in the long run.

Simple changes like using the inhibitor or training staff to properly use it, you will make significant improvements in the life expectancy of your Tag T-10’s battery.