We constantly receive calls from EHS Safety Managers who are concerned about the safety of workers in their assembly plants or warehouses. These contacts allow us to understand first-hand the needs of our customers in the area of industrial safety and, in particular the apprehensions of the specialists in this field.

After having visited many companies we’ve discovered a pattern and recognized that the problems and concerns faced by safety managers repeat themselves everywhere. One of the common issues, for instance, seems to be the concern that a forklift could run over a pedestrian in the many spaces where they interact.

The following are some of the most common answers we offer our customers:

Clearly separate and differentiate pedestrian from forklift circulation areas. All pedestrians should know without a doubt which are the areas where they can walk safely. How can this be achieved? By painting the floor and using pedestrian safety barriers.

Signal all intersections correctly. Intersections tend to be highly dangerous areas. A very effective method to ensure safety around them to is to install doorways to warn pedestrians they are about to cross an area with potential forklift circulation. These doorways can be automatic so that if a forklift travels through an intersection, the door gets locked and the workers will not be able to attempt crossing it. Another alternative is to place a light indicator signalling the crossing.

Minimise the number of collection points of finished and raw materials. These are high risk areas so we must do everything in our hands to reduce them. All workers should know how to access these points and, as far as possible, avoid intersecting with the path of the forklifts. If that cannot be prevented, consider safer alternatives such as using a manual truck for that stretch.

The calls we receive from concerned safety managers, however, do not only pertain to the problems they face day in day out. These managers want to know how can Claitec help. They recognize that Claitec’s solutions will eliminate the problem as well as decrease significantly the number of accidents.

For instance, in cases where forklifts are very close to production lines, the ideal solution is to use the LSA. With this system, the company has the ability to mark an area in which the forklift travels at a slower speed, thus reducing the danger of being ran over.

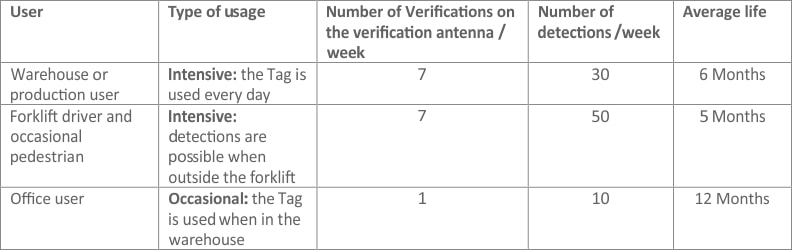

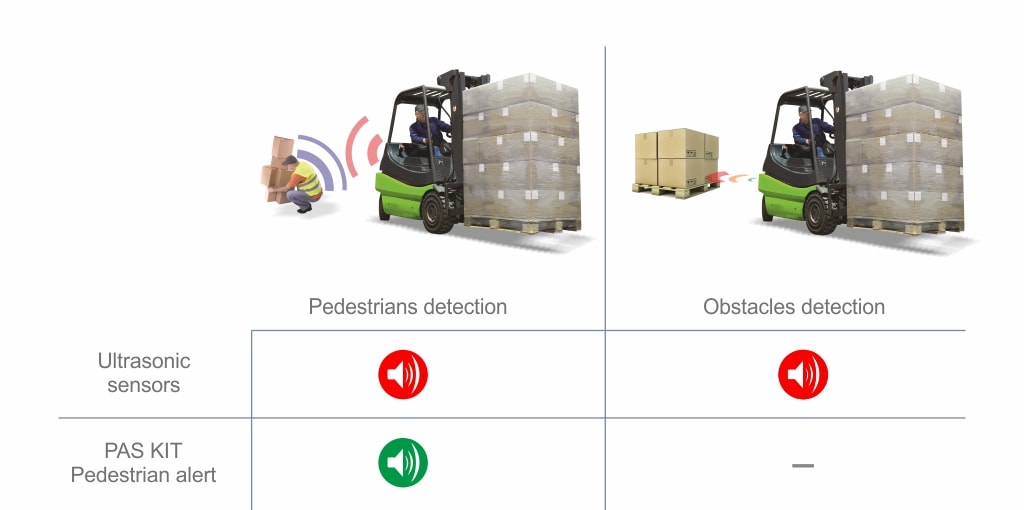

The PAS solution is a particularly useful tool – very popular among Safety Managers – for people who find themselves in the warehouse sporadically such as Quality Control personnel, the Warehouse Manager, external truck drivers, visitors, etc.

Other common enquiries involve low visibility points as far as both pedestrians and a forklift as well as two forklifts. In these cases we recommend using warning systems, traffic lights, warning lights and detection of people and machines to decrease all sorts of risks. You’ll be able to find all the information you need on our solutions in the Products section of our website.

In a nutshell, the Claitec team strongly recommends the following:

- Plan carefully all routes for machines and people

- Physically separate pedestrians and forklift machines

- Signal pedestrians’ paths appropriately

- Automate intersections and use bright signs, traffic lights or lock doors.

- Signal low visibility areas actively

- Protect pedestrians with PAS proximity systems

- Ensure the speed of forklifts is low in the areas of Pedestrian/Forklift interactivity