While it is true that there are many unpredictable elements that can generate a hazardous situation or even provoke accidents in industrial workspace, at Claitec, we have identified the four main factors and have focused our energy on developing effective solutions to address them. These action factors are:

Pedestrian Safety

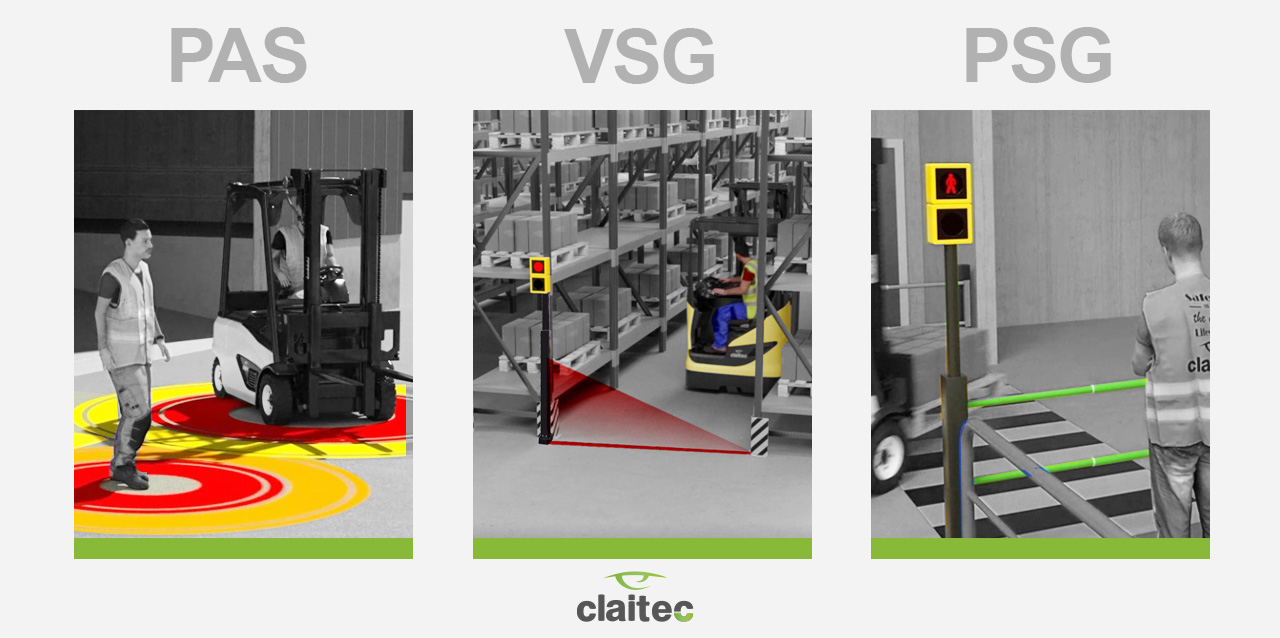

Our priority is to safeguard the integrity of workers moving in areas where they interact with loading vehicles. To cover the risks associated with this factor, we have created the PAS (Pedestrian Alert System), which uses communicative accessories to provide visual and auditory signals that alert workers to potential risks.

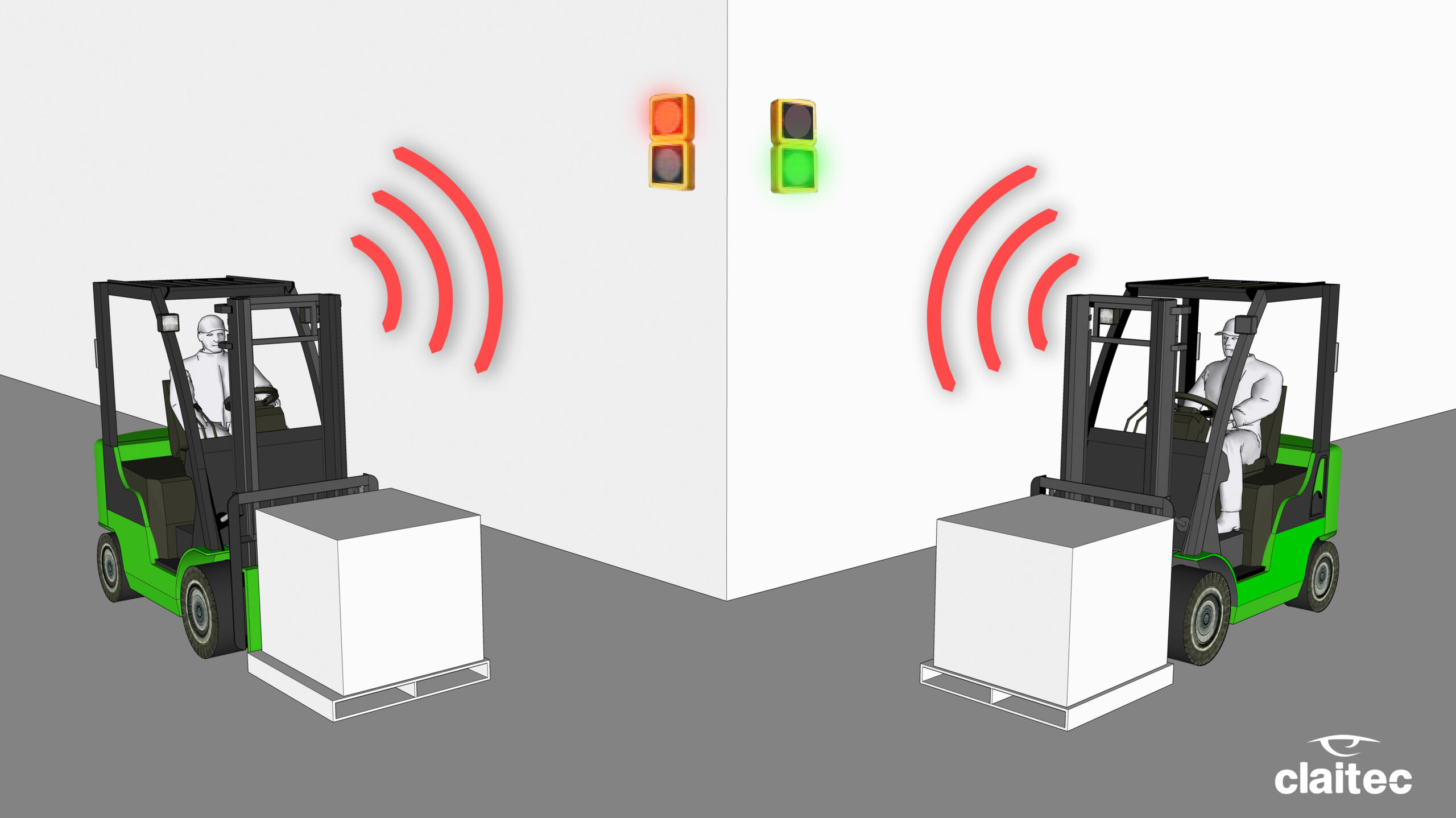

Collision Prevention:

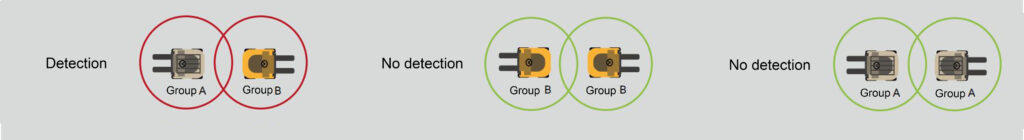

Collisions – whether between vehicles or with people -, are constant risks in industrial environments. Our CAS (Collision Alert System) is installed on forklifts to detect the presence of other vehicles or people properly equipped with obstacle safety tags, emitting visual and auditory alerts for drivers to take preventive measures.

Speed Control

Excessive speed in areas shared by pedestrians and forklifts poses a significant danger. Our LSA (Low Speed Area) solution restricts the speed of forklifts in high-risk zones. Its installation is simple and effective, significantly reducing the risk of accidents.

Traffic Management

Efficient traffic management in areas with a high density of vehicles and pedestrians can prevent costly accidents both economically and, especially, on a human level. Our TCS (Traffic Control System) combines devices that communicate with each other to facilitate coexistence in these areas.

Additionally, our solutions can be combined to enhance their functionality and effectiveness. At Claitec, we continue to innovate and seek constant improvement.Should you have any questions, please feel free to contact us – we are here to help!