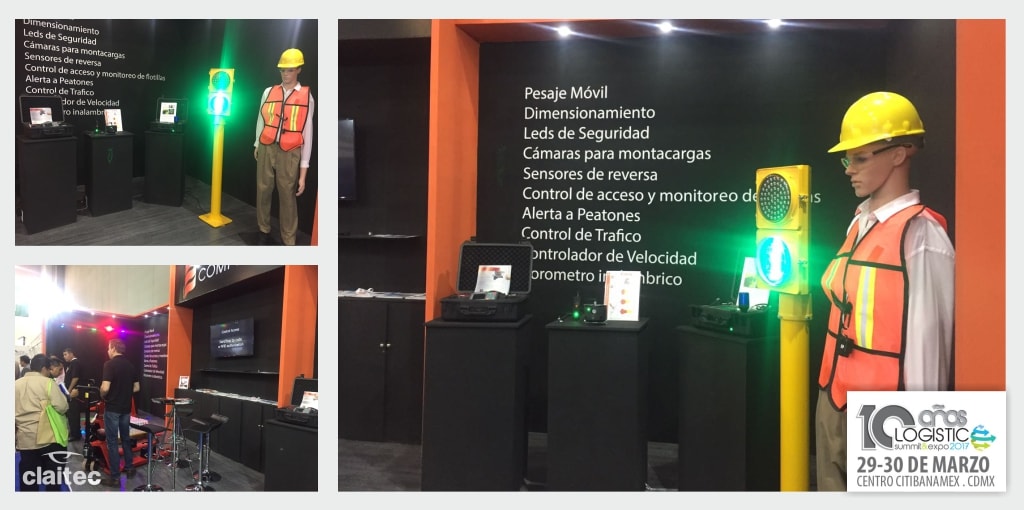

Logistic Summit & Expo 2017, the Latin America’s main trade fair in Intralogistics and Supply Chain, was held a few days ago in Mexico.

Drill Company’s presence at the fair represented an excellent opportunity to promote the CLAITEC brand and products on the Latin American market.

Drill Company, Claitec’s importer in Mexico, exhibited its PAS (Pedestrian Alert System) product ranges and latest developments.

Claitec is delighted with the reception our stand had amongst visitors.