The video we would like to share today is a continuation of the virtual tour presented previously. Both show that at Claitec, we are constantly striving to achieve the highest levels of excellence in our products and services, always prioritising user support through various channels.

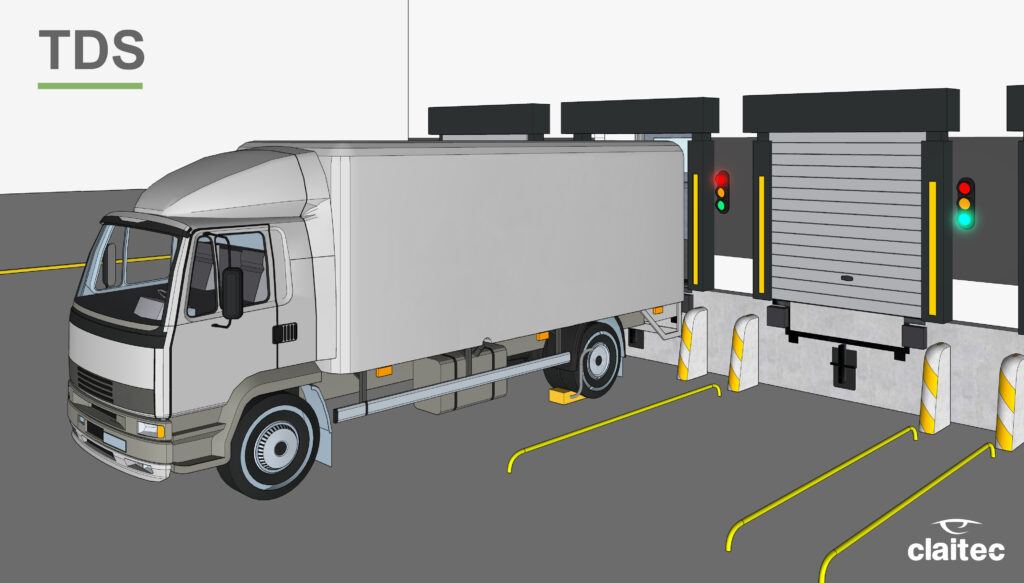

On this occasion, we present both the improved versions such as the TDS (Truck Docking System) , as well as the innovative solutions recently incorporated. Together with those presented in the previous video, these solutions take you on a complete journey that represents Claitec’s proposal and values.

The first of the new products we would like to share with you is the “Truck Inside Dock” – an effective solution which uses a projection on the ground to alert about the presence of a forklift manoeuvrings inside a truck at the loading dock. In addition, the speed of the vehicle can be controlled using our LSA (Low Speed Area) solution, preventing accidents caused by inappropriate speeds during these manoeuvres.

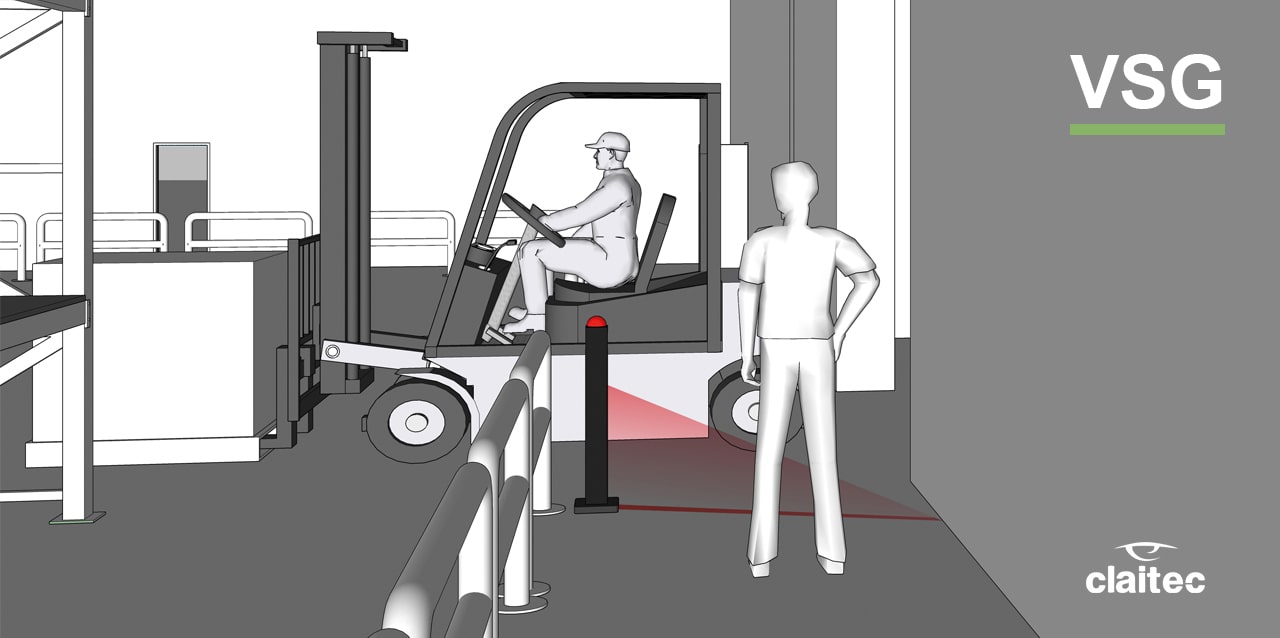

Then, we have the VSG (Virtual Safety Gate), a solution that projects a luminous sign as a virtual gate indicating the right of way at intersections or when a restricted area is crossed without authorisation. In addition to the luminous simulation, it also generates a high-intensity sound signal to help prevent any distraction or recklessness.

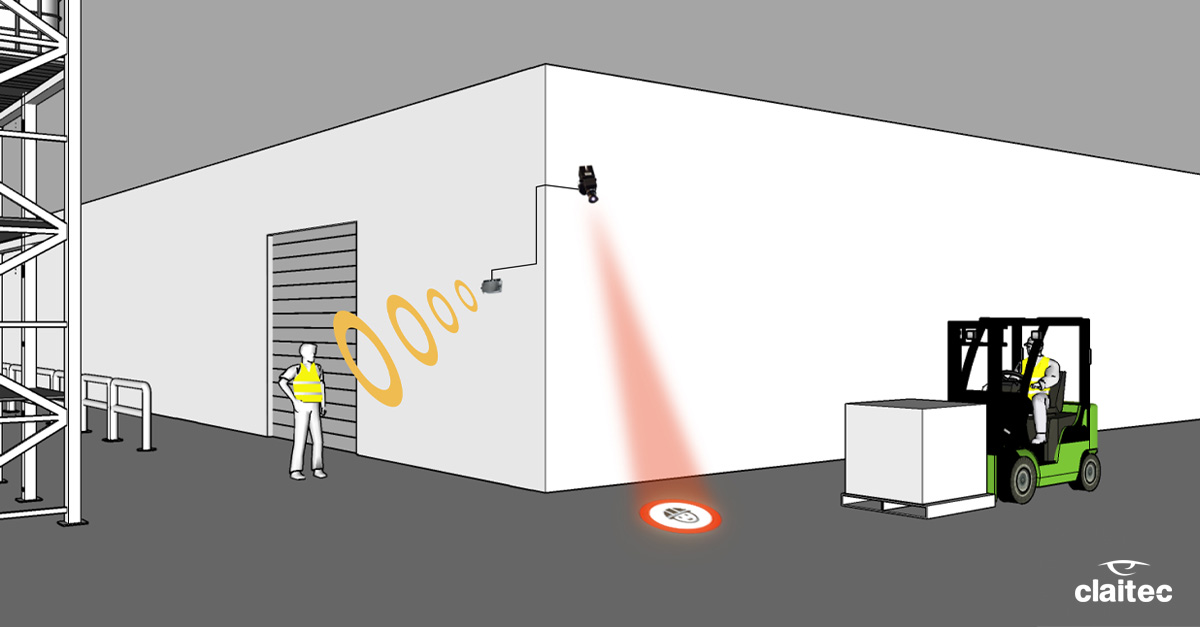

The Crossing Radar is also one of the new products presented in this video. This system uses a radar at intersections with reduced visibility to warn vehicles or pedestrians about the presence of a forklift. It projects a luminous warning on the ground as a vehicle is detected.

As far as forklifts are concerned, our HLS (High Load Sensor) solution addresses the frequent problem of loads with excess height. A sensor feeds the driver constant information about whether the load exceeds the permitted height, improving visibility and preventing collisions.

Another solution used to address risk areas and situations is the so-called Detection Areas, designed for environments where high-risk machinery is frequently used. This solution can prevent serious accidents by stopping a conveyor belt as soon as it detects a person equipped with a personal tag -, hence preventing fatal consequences.

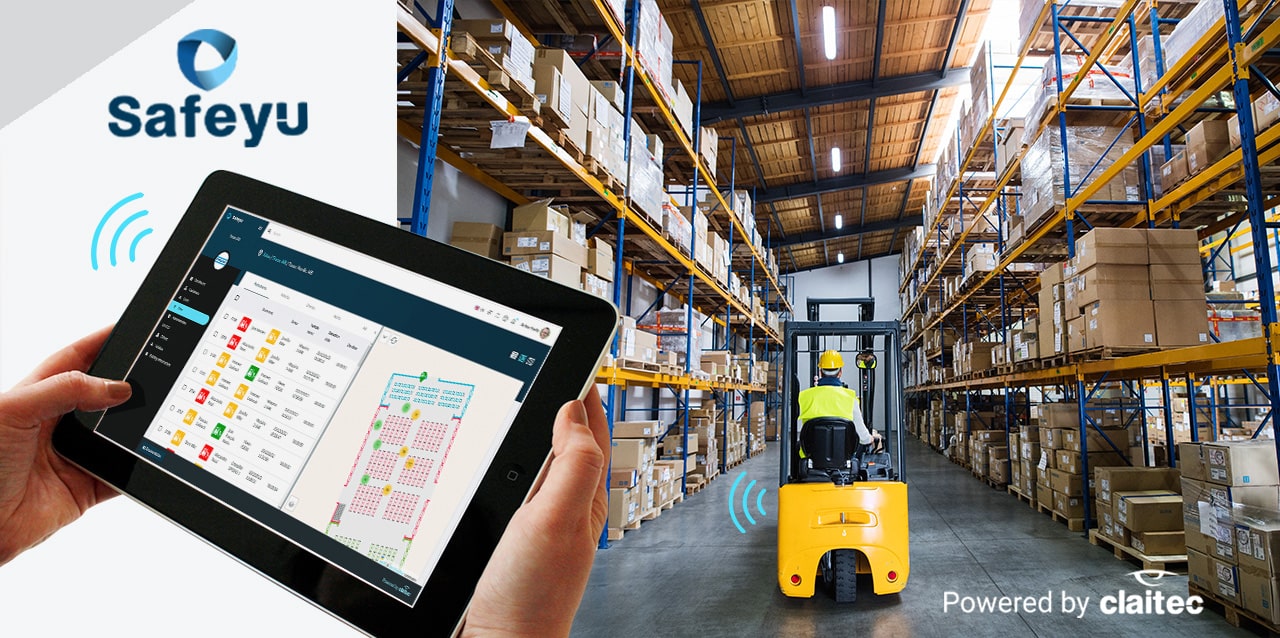

And finally, the latest of our safety solution is the innovative Safeyu platform, a cloud-based platform that allows you to manage all Claitec solutions from one single place, providing a record of all incidents and instructions in real time.

But that is not all, in addition to all the above solutions, we have also created a range of scenes that show our improvements or complement even more our solutions to increase safety. Some of these scenes include the TDS (Truck Docking System) – with improved functions -, and the PSG (Pedestrian Safety Gate), which is shown in operation together with limiting barriers to manage traffic more efficiently.

We hope you enjoy this new journey and invite you to share, comment, and contact us if you have any questions or inquiries.

In today’s post we would like to share with our readers the fantastic experience and results that one of our clients is achieving by using the Safeyu plaform-, a solution designed and developed to prevent accidents at work. Safeyu connects workers, vehicles, and machines in such a way as to identify risk situations in real time and preventively warn workers while generating records that help them draw conclusions regarding prevention, health, and occupational safety in their workspace.

The company in question implemented the Safeyu platform and installed the PAS-G2 System. In addition, their forklifts use the CAS-G2 system, the copilot, and the shock sensor. The operators also carry safety tags with them. Thanks to the monitoring carried out by Safeyu, the firm has now compiled valuable data on detections between forklifts, forklift impacts, detections of people and forklift safety checklist.

With all this information, the company’s occupational safety managers have been able to improve traffic in some of the areas of the warehouse where accidents or incidents previously occurred with higher frequency. They were also able to differentiate pedestrians in areas with a high volume of forklift traffic, as well as detect impacts on shelfs and thus relocate different materials to help work vehicles carry out manoeuvres more easily.

Their day-to-day operations currently work as follows:

- The forklift driver logs into the Safeyu system.

- Once the login is completed, the checklist screens appear so that the user can verify each part of the forklift; for example: whether the brake fluid has been checked, whether the wheels are in good condition. Different options can be personalised by the system administrator.

- Once the checklist has been completed and passed, the driver can start using the forklift.

- If the operator is driving and detects another forklift in the safety zone, a warning will appear on the copilot.

- If a person is detected within the safety perimeter, warning signs will also appear.

- The user can configure the warnings, for instance: whether the co-pilot is required to only warn the driver with an audible alarm, or whether the speed of the vehicle should be reduced when detections take place.

- If the driver collides against a shelf, for example, a warning will also appear in the copilot.

All data generated in the daily operations are sent to the Safeyu platform in real time, so the platform administrator can see the heat graphs, the detections and all the records right there and then, and make decisions or execute changes as necessary.

This allows the safety teams to make decisions based on evidence and operate on the most problematic areas of their daily operations, reducing risks and thus preventing possible accidents at work.

Should you require more information about our solutions, or should you have any questions about our products, please do not hesitate to contact us: we are here to help.

In our continuous search for new and innovative ways to provide helpful solutions for our customers, the team at Claitec has developed a very practical multifunction tag that replaces and unites the tasks performed by other products in one single unit.

Introducing the MT-50 – a new device capable of performing the same functions of the TT-50, TZ-TAG, TZ2-TAG (BI / UNI). This new tag does the same job as all these other devices while also adding power, RF and LF improvements typical of a T -10R, among other things.

The MT-50 can easily be configured using a simple switch to perform the test tag functions which, until now were carried out by the TT-50 – a device designed to oversee the correct functioning of both the RF communications as well as the safety zone generated by the AC-50 Activator.

The MT-50 also performs the tasks of the TZ-Tag – a small device that allows us to detect any forklift equipped with an AC-50 in an established safety zone. Thanks to these devices, a safety area can be delimited in a physical space without needing anyone with the T-10 keyring to be present. This way, when a forklift enters that safety area, the AC-50 triggers an alarm signal on the vehicle, and it even limits its speed.

In addition to the above, the MT-50 also includes the same capabilities of the bidirectional and unidirectional TZ2-TAG designed to detect a forklift equipped with an AC-50 in a safety zone. Thanks to these devices it is possible to delimit a safety perimeter in a physical space without needing anyone with the T-10 keyring to be present. When a forklift enters the safety area, the TZ2-TAG will activate a relay.

Advantages of the MT-50 Tag:

The new tag presents many advantages when compared to its predecessors, including:

- Better detection

- Greater range (going from 5m to 7m in LF -21KHz-)

- Better communication at HF (2.4GHz). This means that it is a lot easier to detect in places where the TZ2-tag and the TZ-TAG were difficult to detect

- It is connected through an IP65 connector

- It is easier to install

- It incorporates a relay

- It can be expanded with additional outputs and inputs

- The configuration of the TZ2 and TT-50 function is easily done through switch

Are you keen to find out more about this solution?

Do you need advice on any of our products?

Don’t hesitate to contact us.

Today we’d like to introduce you to the new Radar Crossing Guard, a device used in conjunction with the Crossing Guard, a system installed at higher levels in warehouses to prevent collisions at intersections.

This solution now incorporates a new “radar” movement detector which guarantees optimal traffic flow at industrial crossings thanks to the reliable and intelligent activation of the Crossing Guard system.

The radar installed in the system can detect any moving object, and it’s even capable of differentiating between vehicles and people. The detection direction can be configured as desired, as well as whether vehicles or pedestrians are approaching, moving away or moving in both directions.

In addition, the Radar Crossing Guard has two fully independent programmable outputs offering complete flexibility in any application. An output boost function makes it an even more versatile solution.

The Radar Crossing Guard is extremely intuitive and very easy to program.

Our clients are also very pleased about how easy it is to combine with other Claitec’s solutions like the VAS Projector at intersections. In this case, when the radar detects a forklift or a person, it projects a signal on the ground at the intersection alerting of a potential risk or indicating the vehicle to “stop”.

Similarly, the radar is also present in the Crossing Guard, combining radars with traffic lights, projectors and bluespots. In this case, it depends on whether the radar detects a person or a machine, or whether it turns on traffic lights or projects a signal on the ground.

Should you be interested in finding out more about our range of industrial safety solutions, please do not hesitate to contact us, we are here to help!

Loading docks are dynamic and strategic spaces with high levels of activity, which are prone to frequent accidents between forklifts, trucks and operators. Claitec has recently developed and updated a tool specifically to minimise risk situations in these spaces -the TDS Truck Docking System.

The TDS System minimises the occupational risks that occur in the loading docks, preventing, for example, a truck colliding with the entrance of the dock or leaving while the goods are being loaded.

It is a simple and easy-to-install solution which, once outside the dock, only requires an exterior traffic light, electronic wedge, distance-measuring radar, detection photocell and connection box. While in the docks, it involves a switch box with an RGB beacon on top, an open-door sensor, and an audible alarm.

An effective system for risky manoeuvres.

The TDS System is specially designed to help the driver safely and efficiently load or unload merchandises on the dock, taking into account that operators, forklifts and truck drivers may be involved during this process.

With the TDS System running, when the truck arrives at the dock the driver knows which entrance is available because the outside traffic light is green. At that moment, inside the dock the beacon will be red, indicating that the door should not be opened. The truck, from the outside, will reverse and, as it approaches the entrance, it will be detected by the distance measuring radar that will indicate with the traffic light outside if the truck is far away (green light), or if it is approaching (amber light).

In addition, this radar will be accompanied by photocells located at the entrance, which will indicate if the truck has reached the entrance, causing the exterior traffic light to signal it with a red light.

When the truck reaches the entrance, the traffic light will start flashing amber to alert the truck driver to put the wedge on the rear wheel of their vehicle. Once placed, it will activate a signal to the internal switch box to notify the operators that they can now open the door, and the beacon will turn green on the internal dock. While the operators begin to carry out their task in complete safety, the outside traffic light will turn red again.

Meanwhile, if for whatever reason the truck exceeds the wedge and leaves without completing the task, a very loud audible alarm will be activated to alert all operators in the area that there is danger, also changing the interior beacon of the dock to red colour.

In addition, the system also offers the possibility of detecting people between the distance measuring radar and the truck, adding more safety and control options to those who operate in loading docks.

Should you have any doubts and/or need our assistance, please do not hesitate to get in touch.

We are here to help!

Dangerous situations leading to occupational accidents arise continuously in industrial spaces with elevated levels of interaction between people and machinery. At Claitec we are constantly seeking solutions that minimise these risks. One such solution is the innovative product we would like to introduce to you today – Copilot. This extremely practical tool functions as a smart complement to the work drivers do, and to assist them in their daily tasks.

Copilot facilitates and increases the flow of information already provided by all Claitec’s safety systems. This simple-to-use touch screen device has multiple functions, but it is mainly used to generate a safety verification checklist of a forklift before using it. It allows to view the detections of forklifts and people and to determine whether the vehicle has had a collision, among other utilities.

With its non-intrusive and intuitive interface, Copilot can display the current status of the components of the PAS System and/or the CAS-G2 on the screen. It allows the driver to know the number of vehicles and pedestrians around him/her at any time, as well as their proximity. On the other hand, it also offers the functionality of vehicle access control, restricting the use of the vehicle to specific users or groups of users.

In addition to this, the information available in Copilot can also be consulted on the web, through the Safeyu platform. Both platforms – Copilot and Safeyu – are connected and share information from the various sensors, as well as from the input and departure of drivers and other events related to the vehicle.

This video on Claitec’s participation in the Logimat fair clearly shows how Copilot works.

Should you have any questions on this system, or any other of Claitec’s safety devices, please do not hesitate to contact us.

We are here to help!

Claitec is proud to introduce Safeyu, an innovative solution designed by our team to prevent occupational accidents. Safeyu connects workers, vehicles and machines to easily identify risk situations in real time and preventively warn the person/s at risk.

Safeyu is a modern, practical, and powerful product that allows logistics companies to ensure and control the safety of their workers, minimising any potential risk. Thanks to all the devices developed by Claitec, all the activity that occurs in the company is recorded and can be monitored from the Safeyu platform.

From the Safeyu website, the company registers its workers, its machinery, its devices, and its headquarters in order to later be able to keep track of all of them and draw key conclusions in terms of prevention, health and occupational safety.

The home page shows different graphs corresponding to the data coming from the devices, be it accident details, potential accidents, or indicators of change status of a device, for example. In addition, this section allows the person in charge to get an idea of the general circumstances of the company to take preventive measures for the future.

In the users’ section, you can access the list of people authorised on the platform, allowing you to individually see the data and events in which they have been involved, as well as being able to configure settings.

In the sites section you can see the company’s different locations, with their corresponding buildings and floors, a map a tracking the vehicles, the events that have occurred in a certain period of time, heat maps, and even the location of traffic control devices – just to mention a few possibilities.

We have grouped the devices into three categories:

- Firstly, we find the drivers where the tags are registered, as well as permissions can be assigned or rejected, we can also see the checklist and login records.

- Secondly, we find the vehicles. We can also access all detections and impact records from the devices installed in machines.

- Lastly, would be the building infrastructure which allows the devices of the infrastructure to be seen, which are located at a fixed point and manage the traffic.

Do you have any questions about Safeyu or any other of Claitec’s products? Get in touch! We are here to help!

Ensuring the integrity of employees our industries is an absolute priority for Claitec. That is why we are continually looking for improvement tools that prevent occupational accidents and contribute to safety and health at work. And today, we would like to introduce you to our most recent development, the VSG (Virtual Safety Gate) Solution.

The VSG Solution consists of a virtual door operated by photocells and activated by movement. When access to a certain area or intersection is not allowed, the VSG activates a warning system that projects a red line on the ground.

If the door detects a forklift, a line is projected on the ground indicating that access is not allowed. If the driver crosses decides to cross the virtual door against the warning, a light and a sound alarm switch on, and a signal is sent to the vehicle so that the driver is aware of the danger.

Furthermore, this innovative solution can be easily combined with other Claitec tools, such as the VAS Solution. In this case, a pedestrian crossing can be created and program it so that when the door system detects a forklift, the pedestrian crossing is cancelled.

Please note:

It should be noted that the VSG Solution stands out for its multiple benefits and many ways of adapting to the environment where it operates. For instance, if a warehouse does not have any doors, this system can solve the work dynamics by generating virtual doors, thus making the place safer and more practical, and avoiding the need to invest in enclosures.

This system also requires no maintenance, takes up almost no space and is easy to install, thus becoming a highly useful solution for any industry.

Should you have any questions and/or require our advice, please do not hesitate to contact us.

We place our focus today on two products developed by Claitec that have been widely accepted by our customers over the last year and that stand out for their practical and effectiveness of their operation: the T-10R tags and T-10R Badge.

The Tag T-10R is an evolution of the T-10 Tag. The performance of the range radius and the ease of detection in the new device are dramatically improved. It also features a battery with a one month autonomy minimum and it is wirelessly rechargeable, making daily tasks a lot easier. The T-10R tag comes with a high-intensity LED lighting, which helps with rapid detection and it ensures the visibility of the person wearing the tag. With a 360° angle light, it can be seen from anywhere, upping the safety levels in our workspaces and preventing many occupational accidents.

In addition, the new tag has a vibration system, which is incorporated as a new alert channel for operators in the presence of another person or vehicle. And it also generates a high intensity sound warning, completing a wide range of alert forms that improve safety standards in our industries.

The T-10 R Badge, on the other hand, is the ideal solution for the protection and control of visitors in industries. It is currently being already widely used by our clients, providing very good results in improving work safety and the reduction of accidents.

Persons registering as visitors are given a T-10R Badge tag on the card with their credentials. What that means is that by only carrying a simple card the person is protected from forklifts and loading machines. The T-10 R Badge tag is an adaptation of the new T-10R tag but with the unique feature of being a card holder which makes it a lot more difficult for the operator or the person who is visiting to forget it or lose it.

If you have any questions and require our advice, do not hesitate to contact us.

Always conscious of the vital role that forklifts play in the daily work of our industries today, at Claitec we are constantly seeking to provide solutions that complement their operation, make them more effective and safer, facilitating drivers’ tasks, and ultimately, helping prevent accidents.

In today’s post we’d like to introduce you to one of the latest tools we have developed after listening to several of our clients’ suggestions. After learning about some of the problems they face and some of the accidents that occur because of the excess height in the load transported by the forklifts, we created an innovative tool known as the High load sensor HLS.

The HLS warns forklift drivers as soon as it detects that the loads picked up exceed the permitted heights or predefined measurements. Thanks to the light and sound signal sent to the driver if the load exceeds the maximum allowed, we now prevent unsafe movements that could lead to an accident.

In addition, the HLS Solution is presented as an ideal complement in the prevention of accidents in warehouse doors, a weak point managed today by installing a bidirectional Tz2 Tag on the warehouse doors and incorporating the PAS System on the forklifts. These solutions make it possible for drivers to be warned when a vehicle approaches a door that is closed or not fully open.

If you have any questions, if you want to know more about our solutions or if you require our advice, do not hesitate to contact us.