To successfully eliminate the risk of accidents and health threats that lurk around in the workplace, it is necessary to conduct frequent safety checks. To do so, companies must rely on trained personnel and the necessary equipment to ensure a full and detailed review of risk areas. Both the gathering of evidence and the writing of reports should be done in a complete and professional manner to meet the appropriate safety standards.

Now, entrepreneurs and inspectors have a wonderful tool to help them perform these tasks and minimise the time spent on the audit – SafetyCulture’s free application: iAuditor.

Since its release in February 2012, iAuditor has been used in over 80 countries worldwide with more than 25,000 daily safety audits recorded. This application can be used in mobile devices such as iPads, Android tablets or smartphones with any operating systems. It features a simple and intuitive interface that allows people without any experience on this type of applications to use it easily. It also allows the user to point at specific objects, it answers questions and takes pictures to conduct a professional audit with all the elements that should comprise it.

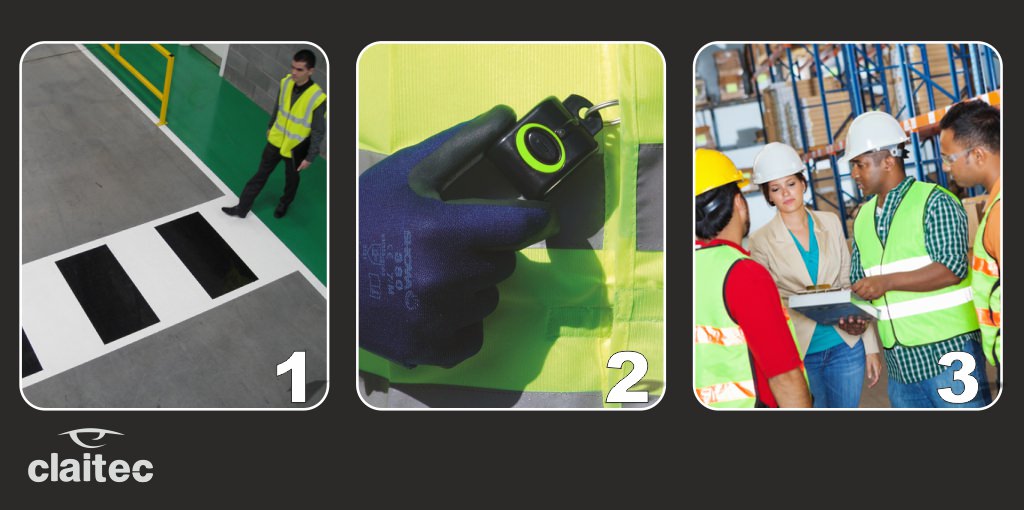

The safety inspector is able to take pictures with the mobile device and use them as evidence of the state of the workspace. Other elements can also be added such as arrows, diagrams, symbols and all those needed to highlight the details found. Also, you have the ability to add notes and comments to make the statement of results more explicit.

When the audit is complete, iAuditor generates a full technical report that is well very well structured and of a very high quality. The free version of this app allows the user to export the report in PDF format, while a premium account allows storage in a wide range of formats like MS Word, XML, JSON, and CSV. Traditionally, these reports could take hours to complete, but iAuditor is able to generate them in seconds with photographs, signatures and all the components a report should include.

One of the most versatile features of the application is its ability to create custom templates with lists of activities to be undertaken. SafetyCulture, the creator of the application, has produced an extensive range of useful templates for all types of practices, industries and user needs, such as for example, the Safety in the Warehouse template which, is suitable to a very large number of situations. The company’s online repository is known as Audit Forms, and there is possible to find all kinds of audit templates. Currently, there are over 50,000 templates in their library and every day new templates are loaded by the company or its users.

Claitec is developing a set of more practical templates for the benefit of our customers which are based on the experience and knowledge of our expert staff. We are hoping that users will be able to conduct their needs assessments and safety audits to ensure optimal performance of their PAS (Pedestrian Alert System) and LSA (speed limitation zones) solutions.

iAuditor is yet another example of how technology can be used to improve industrial safety and worker protection.