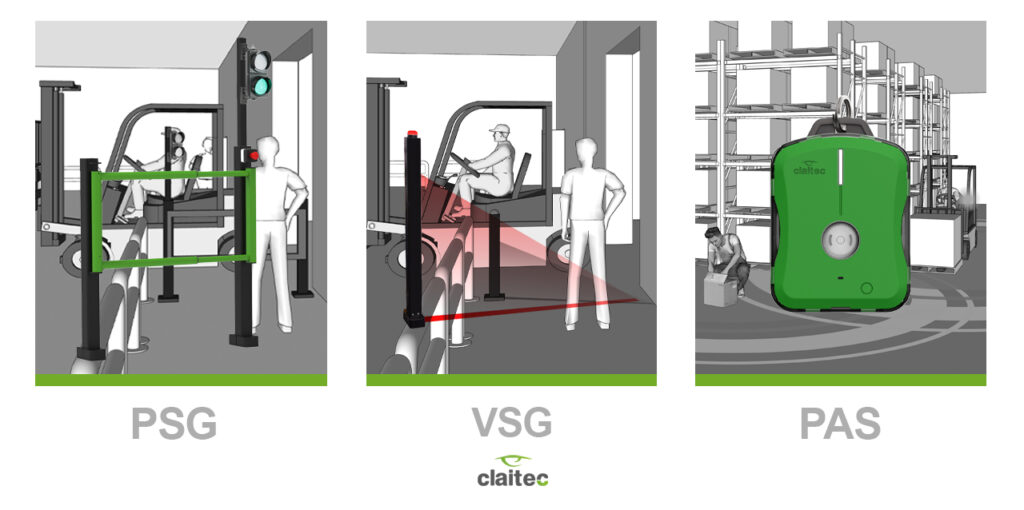

The VSG system (Virtual Safety Gate) is a virtual gate that warns drivers and pedestrians that passage is not allowed in certain areas or intersections by means of an alert system that projects a red line on the ground.

The virtual safety gate has been providing Claitec’s customers with valuable assistance and it’s becoming a great ally in improving safety and preventing work accidents in industrial corridors.

The VSG system can be easily placed at the entrance point of any aisle to notify forklift drivers when other vehicles or operators are circulating along the same aisle. The gates can be fitted either with an RGB pilot light on the post or with a traffic light that indicates whether passage is allowed or otherwise.

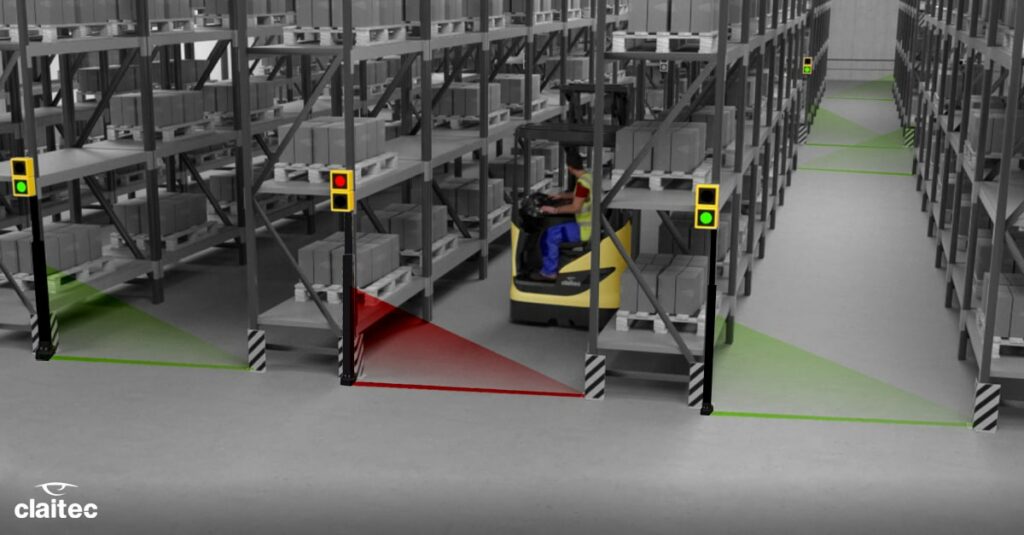

If there are no vehicles in the corridor, the VSG will project a green line on the ground. If a vehicle enters the corridor, it will automatically change the projection to red until the vehicle leaves the area, making it easy for the drivers to determine whether they can advance or whether they must wait.

There are several options to help detect if a forklift is circulating along the aisle:

- VSG – Internal configuration.

Configuring the VSG itself will help detect a vehicle as it enters or leaves an aisle, and automatically proceed to activate the line projectors: red when it detects the presence of a forklift that has not yet left, green when there is no forklift and /or has already left.

- VSG + PAS System.

The VSG is connected to an MT-50 and in the forklift, we have installed a PAS kit. So, when the MT-50 of the VSG detects the vehicle, it directly changes the projection colour to red, changing it to green only when the vehicle leaves the corridor.

- VSG + LSA System.

In this case, the VSG is connected to an LSA control unit, and the forklifts incorporate coded reflective bands. When a vehicle passes through the VSG, the VSG automatically reads its coded reflective stripes and changes the projection from green to red, alerting of the presence of a vehicle in the aisle.

- VSG + CAS-G2 System:

The VSG is connected to a CAS-G2 and in the forklift we have installed a CAS-G2 system. When the CAS-G2 detects the vehicle, it directly changes the projection colour to red, changing it to only when the vehicle leaves the corridor.

Should you have any questions and require our advice, please, do not hesitate to contact us. We are here to help!