Claitec’s work and day to day efforts centre around a simple mission – to provide solutions that ensure through the application of innovative and intelligent solutions that our customers improve the safety and health in their workspaces, reduce workplace accidents, and generally better their efficiency levels when performing different tasks.

Our ultimate goal is to improve and advance with confidence while listening to the needs of the different actors with whom we come into contact. And in these difficult and uncertain times, being able to see that our solutions are increasingly used and supported by customers fills us with pride and it motivates us to continue working as hard as always.

The results up to date speak for themselves.

We can say with great satisfaction and joy that more than 30,000 people and 7,000 machines or work vehicles have benefited or have been protected by our innovations.

In addition, we have also created protective solutions such as:

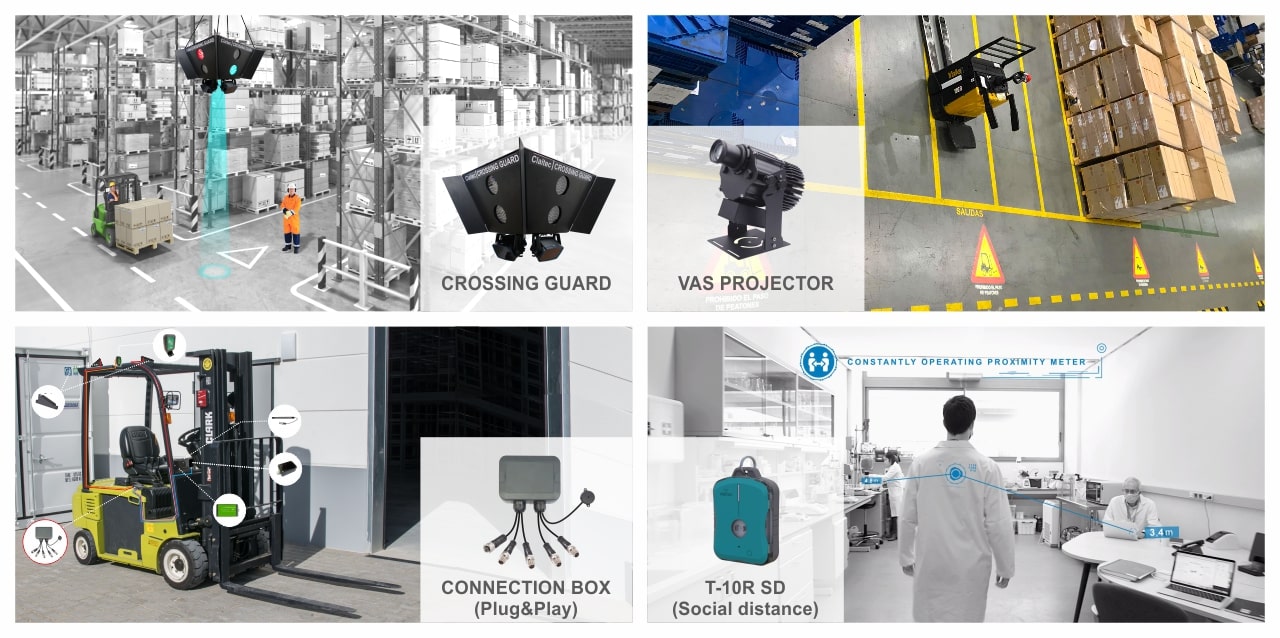

- The PAS system, for the prevention of collisions between people and forklifts.

- The crossing guard, as innovative system designed to prevent collisions at intersections.

- The LSA solution for forklift speed control.

- The VAS system, which warns pedestrians and / or forklifts about potentially hazardous situations by projecting signals on the ground.

- The TCS solution, which separates pedestrians and vehicles in workspaces.

In addition, our devices are present in more than 30 countries around the world, in sectors as complex as they are varied. Having earned the trust of so many people, of so many companies, in all these years of work, is the best reward to our team’s effort.

In these difficult and uncertain times, these figures are a source of great joy for us and the best motivator to continue working committed to our mission to continue paving a safe, responsible, and confident path.

Should you need more information on how to improve your levels of occupational safety, please don’t hesitate to get in touch.

The team at Claitec is here to help you.