We all know the critical role forklifts play in our industries. They are irreplaceable tools that provide us with efficiency and results. However, the coexistence of this machines with workers on foot poses a significant threat to occupational safety and it is a generator of work accidents, run-ins or major damages.

That’s why in this post we want to discuss three key tools that help segregate forklifts from pedestrians and significantly improve traffic in our workplaces.

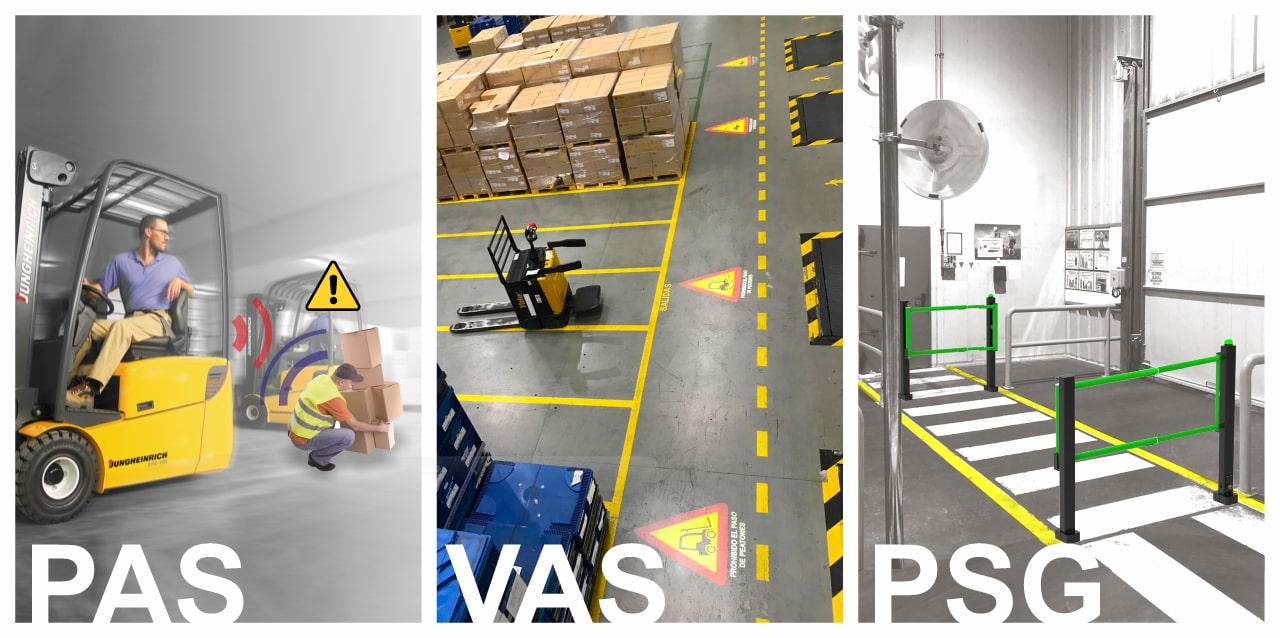

1) PAS Pedestrian Alert System:

A reference tool in this area and an essential tool for any industry. The PAS system warns forklift drivers as soon as it detects a person at adjustable distances from 1 to 6.5 meters. This system is capable of differentiating between people and objects, and it even detects workers who are behind a wall or a shelf. A tool that has achieved remarkable results in very different contexts, the PAS system complements easily other safety measures in our workspaces.

2) VAS Solution (Visualisation of Safety Alerts):

Our Visual Alert System, an innovative development designed to warn pedestrians and/or forklift drivers of a potentially risky situation by projecting signals on the ground. Such signs are highly visible to operators and easy to detect, and they become very useful in spaces with high frequency of pedestrian movement. The signs emitted by the VAS solution stand out against the more basic traditional panoramic mirrors and signs used in industries up until now.

3) PSG System (Pedestrian Safety Gate):

A safety gate designed to reduce risk situations in high-activity environments. This system has two functionalities: creating safe pedestrian crossings and restricting entry to improperly protected personnel. It combines with the TCS Traffic Control system, automatically interacting with other Claitec devices to block pedestrian crossings in the event of an approaching forklift.

Should you need more information on how to improve your levels of occupational safety, please don’t hesitate to get in touch.

The team at Claitec is here to help you.