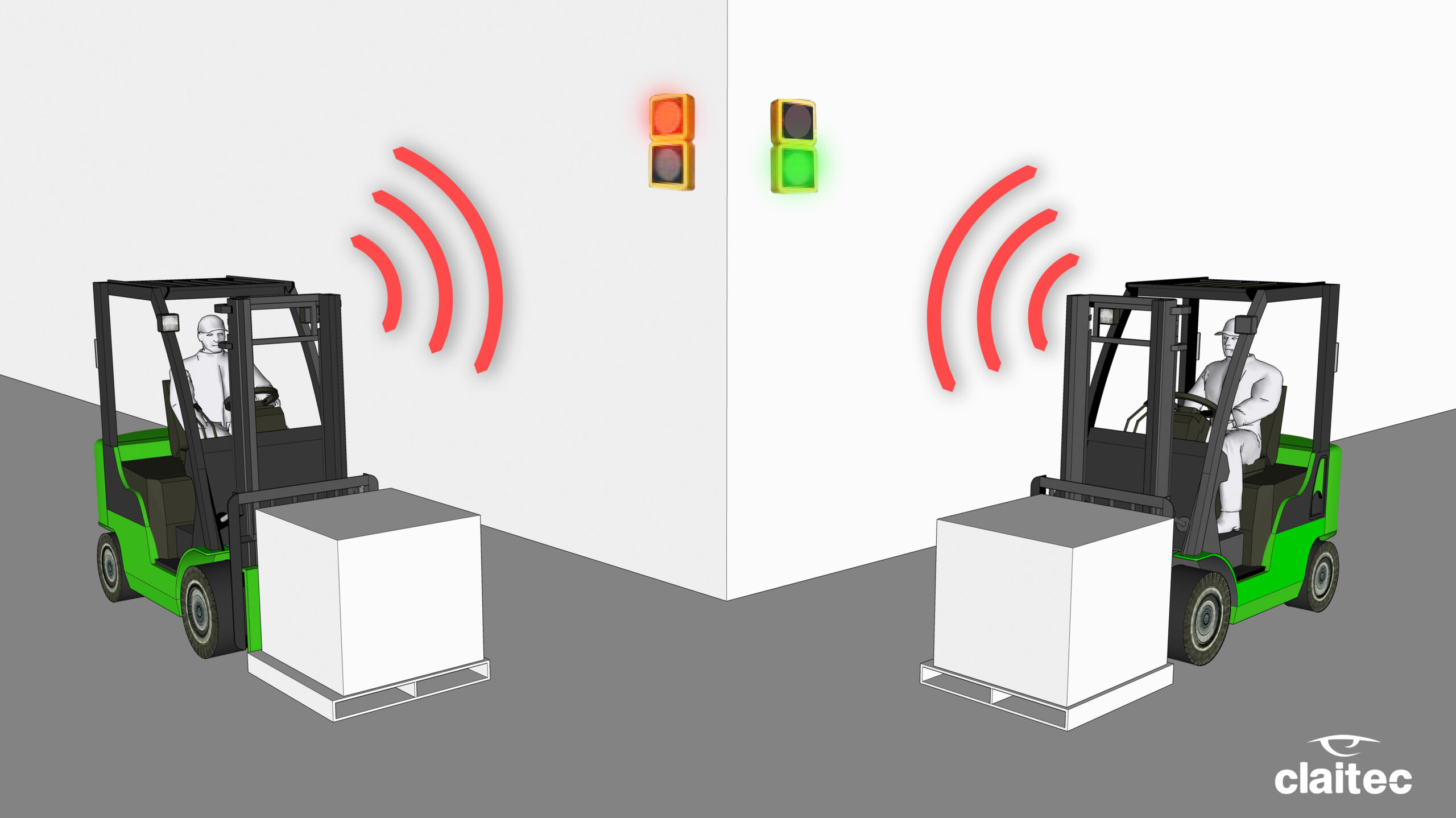

In any industry where forklifts or other types of mobile machinery operate, there is a real risk of collisions and accidents. These hazardous situations can be caused by various factors, such as reduced visibility due to blind spots, intersections in narrow aisles, or areas with limited manoeuvring space for drivers.

The Cas-G2 system developed by Claitec provides an effective solution to address these issues by alerting drivers to the presence of nearby vehicles. The installation of Cas-G2 on the forklift is straightforward and allows for the configuration of different detection zones that can cover up to 40 meters, enhancing safety and production efficiency by distinguishing between objects and vehicles.

The Cas-G2 system offers numerous advantages. In this post, we will focus on one of its most innovative features: the Group Function.

What does this function entail?

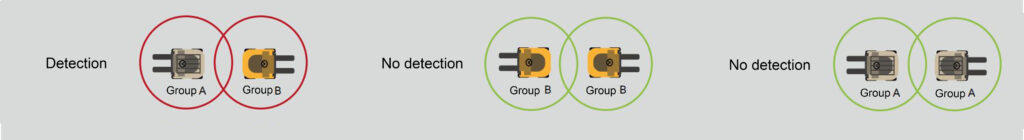

The anti-collision system Cas-G2 allows different groups of machinery operating in the same workspace to be differentiated, thereby helping to prevent accidents and improve the coexistence of vehicles.

For example, forklifts equipped with the Cas-G2 system can be detected by AGVs (Automated Guided Vehicles) operating in the same space simultaneously, avoiding collisions. However, these AGVs may not detect each other when unnecessary, facilitating a smoother, safer, and more productive workflow.

It is possible to create up to 8 different groups of machines

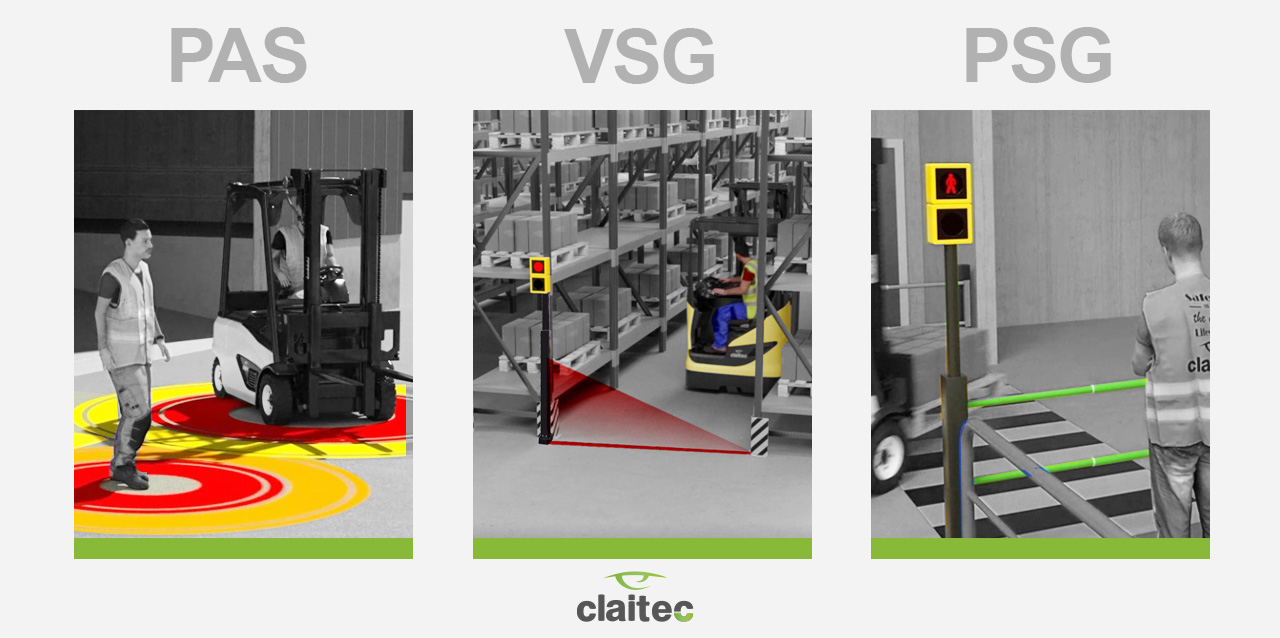

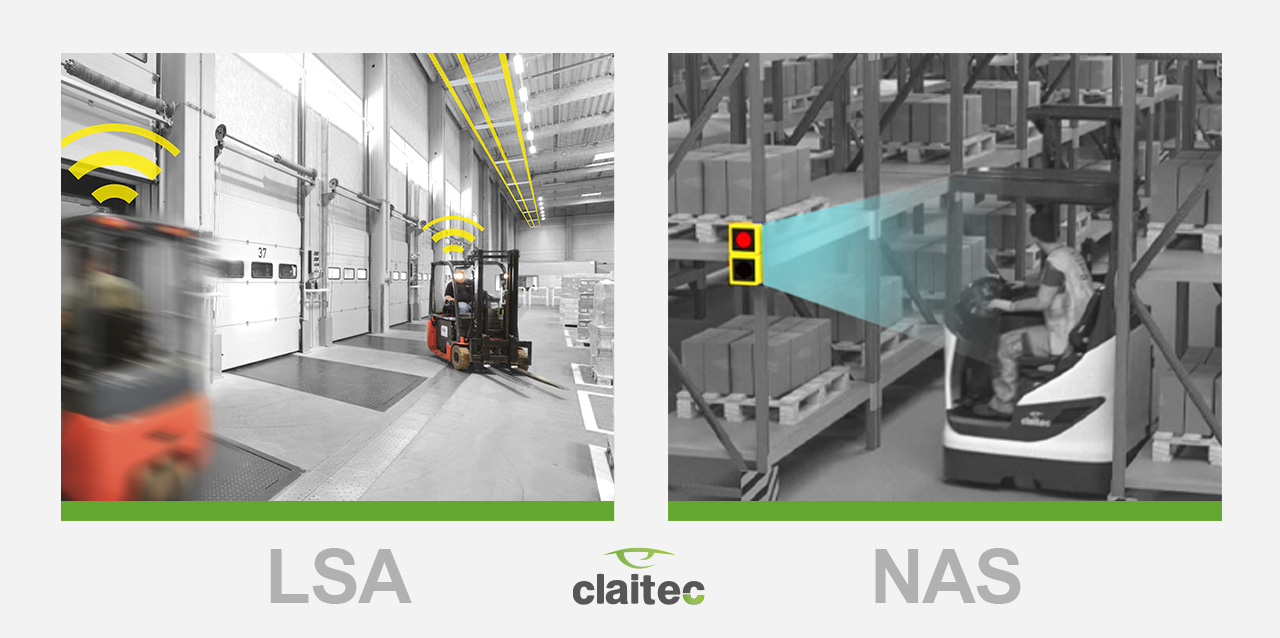

It’s also essential to highlight that the Cas-G2 system seamlessly integrates with other solutions developed by Claitec, increasing overall effectiveness and allowing drivers to focus on their tasks, knowing that safety is the company’s top priority. This, in turn, boosts confidence and contributes to an optimal working environment.

If you wish to obtain more information about this system or explore our products, please don’t hesitate to contact us. We are at your disposal to provide further details.