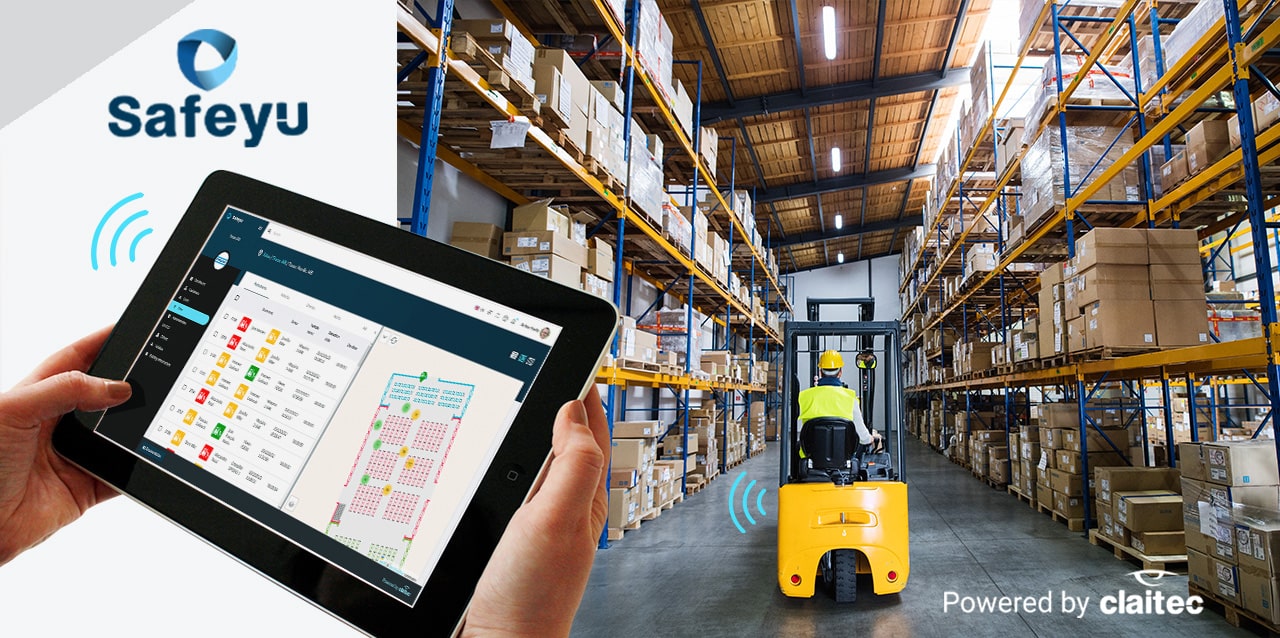

At Claitec we have often witnessed that a significant portion of risks and workplace accidents in industrial companies occur in shared spaces between work vehicles and operators.

Collisions, impacts, injuries, and damages are just some of the most common consequences in such spaces when there are insufficient occupational safety measures in place.

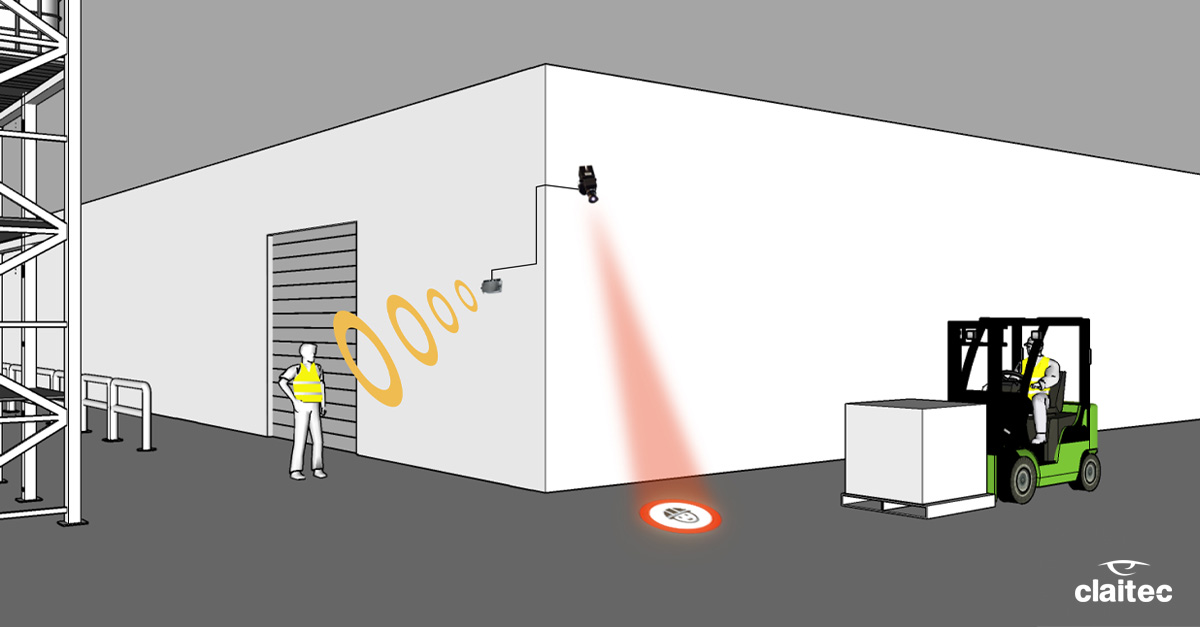

Thanks to the feedback from our customers, we have developed a tailor-made solution to address this problem: the Crossing Guard, an innovative device installed at warehouse heights to help prevent collisions at intersections.

This system protects both operators and vehicles, making a significant contribution to occupational safety by reducing risks and preventing workplace accidents.

Its operation is very simple and practical: as a vehicle or person approach the intersection area, they receive visual alerts from the traffic lights and the projection of the bluespot or VAS projector to determine if they have the right of way or not.

This ensures increased safety to prevent collisions.

The Crossing Guard system uses radar technology, which is capable of differentiating between a person or a forklift passing through as well as detecting if the forklift is approaching or leaving the intersection.

The system is extremely versatile and specifically designed to be used in warehouses, depots, loading docks, or industrial spaces with high-risk intersections where there is a convergence of operators and loading machinery.

Furthermore, it features a robust aluminium structure, and its installation and handling at heights are straightforward.

Additionally, it is essential to note that neither the operators nor the forklifts need to carry a device to be detected with this technology.

Another highlight is the design of the equipment, which includes fins for light separation to prevent other traffic lights from being visible from the same angle, thus avoiding confusion.

Should you have any questions, specific inquiries, or to obtain more information about our solutions, please do not hesitate to contact us. We are here to assist you!